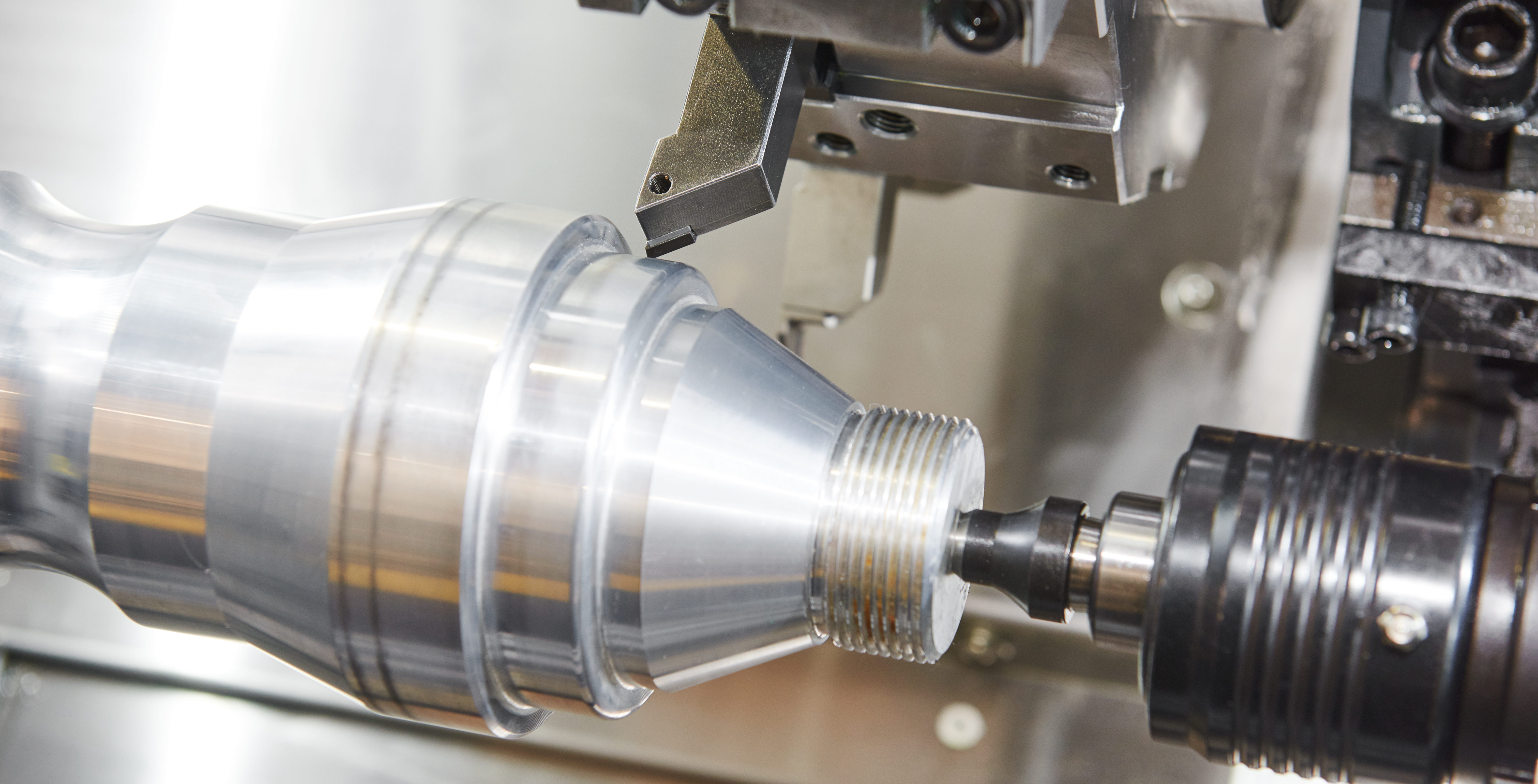

CNC TURNING MACHINING

CNC lathe machining is a kind of high-precision and high-efficiency automatic machining machine with digital information to control the displacement of parts and tools.

Emergency Services

We have machines for sample machining only. If your project is urgent, just send your drawing to our email or call us, we will assess your drawing priority. And try our best to meet your delivery time.

Know More Of CNC Turning

CNC turning machining is a machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of variable part varieties, small batches, complex shapes, and high precision, and to achieve high efficiency and automated processing.

- It is easy to ensure the accuracy of each processing surface of the workpiece; during processing, the workpiece rotates around a fixed axis, and each surface has the same axis of rotation, so it is easy to ensure the requirement of coaxiality between the processing surfaces.

- The cutting process is relatively stable; except for intermittent surfaces, the lathe machining process is generally continuous, unlike milling and planing. During one pass, the cutter teeth are cut in and out multiple times, resulting in Impact.

- Suitable for the finishing of non-ferrous metal parts; some non-ferrous metal parts have low hardness and good plasticity due to the material itself, and it is difficult to obtain a smooth surface by other processing methods;

The tool is simple; the turning tool is the simplest type of tool. It is easy to manufacture, sharpen and install, which is convenient for selecting a reasonable angle according to specific processing requirements.

- The processing quality is stable, the processing accuracy is high, and the repeatability is high, which meets the processing requirements of the aircraft.

OTHER SERVICES

Builds five production workshops for CNC milling, CNC turning, stamping, bending and powder coat. The business covers automotive parts, rail transportation, new energy and other industries.

QUALITY GUARANTEE

The product quality has achieved an ISO9001-2015 quality management system certification. In terms of quality control, there are strict standards from production to testing, from operating staff to management, and 100% of good products are released. All sizes are tested and recorded one by one. Striving to give customers the most assured quality service. Longwang is willing to work together with you to develop together for a better future!

FREE QUOTE

Do you need help with customized fabrication machining? Fill out this form to get in touch.

OFFICE LINE

0769-82763299

EMERGENCY

+86 18988716988

WORKING HOURS

8:00am – 5:00pm

OFFICE LINE

0769-82763299

EMERGENCY

+86 18988716988

WORKING HOURS